Lýsing

THE MICHELL CARTRIDGE STORY

Developing your own range of cartridges is no easy task. It requires a lot of research and know-how. Knowing what you want from a cartridge is one thing… producing one is a different matter. We wanted to produce three, so we decided to bring in experts.

We found a partner with a long history of creating world-class high-end cartridges and decided to start with our top-of-the-range Cusis M.

Having decided that a moving coil cartridge was the only option to deliver the realism and neutrality that we were shooting for, our partners then suggested stylus profiles, cantilever materials, and coil materials and designed a bespoke generator that would deliver a truly high-end presentation.

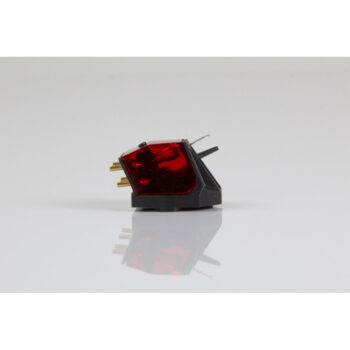

We then set about designing an enclosure that would allow the generator to perform at its best. Michell has a wealth of engineering and material experience, and we had already planned a cartridge body with our initial partnership with Benz, so we decided to use that design but produce it using carbon-loaded acrylic. We have used this material extensively in our turntable platters and found it to be acoustically perfect as it dampens resonance and massively reduces airborne vibrations.

To control internal resonances and vibrations from the tonearm, we knew the cartridge needed a large, rigid chassis with high mass. We chose a single piece of machined aluminium, which gave us the mass we required and the ability to attach the generator, body, and terminal plate easily.

After the initial testing of the prototype, we began fine-tuning each part of the cartridge and really developing our knowledge of what it takes to make a great cartridge.

This was the longest part of the process, with hours of listening and deciding what components to change or modify to get the perfect balance.

We developed the Cusis M without allowing cost to become a factor. We were only interested in maximum performance. The result is a cartridge that delivers a performance worthy of the finest turntables and tonearms available at any price.

Once the Cusis M was completed, we began to develop two more cartridges based on the Cusis M, but aimed at lower price bands. This resulted in a range of moving coil cartridges that cover all price points and offer best-in-class performance.

Michell Cusis M – High End

Michell Cusis S – Mid Level

Michell Cusis E & E/H – Entry Level

An array of five-star reviews and group test winners testify to the years of development that went into creating the Michell Cusis Moving Coil cartridges.

MICHELL CARTRIDGE SPECIFICATIONS

| Model | Cusis E | Cusis E/H | Cusis S | Cusis M |

|---|---|---|---|---|

| Tracking Force | 2.0g | 2.0g | 2.0g | 2.0g |

| Loading | 100 ? | 47K? | 100 ? | 100 ? |

| Frequency Response | 20-25000 Hz | 20-25000hz | 20-35000hz | 15-45000Hz |

| Output Voltage | 0.35mV | 2mV | 0.4mV | 0.25mV |

| Weight | 8.9g | 8.9g | 8.9g | 8.1g |

| Cantilever Material | Aluminium | Aluminium | Boron | Boron |

| Stylus Profile | Elliptical | Elliptical | Shibata | Ultra-precise Microline |

| Channel Balance | <1dB | <1.5dB | <1dB | <1dB |

| Channel Separation | 23dB | 22dB | 25dB | 28dB |

| Compliance | 8×10-6cm/dyne | 8×10-6cm/dyne | 8×10-6cm/dyne | 8×10-6cm/dyne |

| Tracking Ability | 70µ / 2.0g | 70µ / 2.0g | 70µ / 2.0g | 70µ / 2.0g |

| Internal Impedence | 4.5 ? | 130 ? | 4.5 ? | 3 ? |

| Type | Moving Coil | Moving Coil | Moving Coil | Moving Coil |

| Coil Material | Pure 30µ Copper | Pure 30µ Copper | Pure 30µ Copper | Pure 30µ Copper |

| Run-in Period | > 40 Hours | > 40 Hours | > 40 Hours | > 40 Hours |

| Body Material | Acetyl | Acetyl | Acetyl | Carbon Loaded Acrylic |